Cutting Costs in Construction with Automated MEP Clash Resolver

Key Highlights

- An automated MEP clash resolver is a software that helps to resolve clashes between MEP systems in BIM models.

- Using an automated clash resolver can help to save time and money on construction projects.

- Automated clash resolvers can help to improve the accuracy of BIM models and reduce the risk of errors.

- There are a number of different automated clash resolvers available on the market.

- When choosing an automated clash resolver, it is important to consider the needs of the project.

Introduction

The construction industry is increasingly adopting Building Information Modeling (BIM) to enhance project efficiency. A key aspect of BIM is the ability to detect and resolve clashes between different building systems, particularly MEP systems. This is where automated MEP clash resolvers play a crucial role. By automating the clash detection and resolution process, these advanced software solutions offer significant benefits in terms of cost savings, time management, and improved project outcomes.

What causes clashes in BIM Model?

In the realm of construction, where precision is paramount, BIM clash detection emerges as a critical process. Clashes, essentially conflicts or interferences between different building components, can arise due to various factors. These factors include human error during the design phase, discrepancies in data from different disciplines, and the inherent complexities of coordinating multiple systems. BIM clash detection helps identify these clashes early in the design process.

There are different types of clashes encountered in BIM models. Hard clashes represent physical overlaps between elements, such as a duct passing through a structural beam. Soft clashes, on the other hand, pertain to spatial clearances and code violations, like insufficient space for maintenance access around equipment.

The Role of Automated MEP Solutions in Construction Efficiency

Automated MEP solutions are revolutionizing the management of clashes in construction projects by generating clash reports and implementing best practices. In contrast to traditional manual methods that are labor-intensive and error-prone, automated solutions utilize advanced algorithms and rule-based systems to swiftly and accurately detect clashes. This not only expedites the coordination process but also enables more iterative design revisions, ultimately resulting in optimized building designs and reduced rework during the construction phase.

"Good buildings come from good people, and all problems are solved by good design"

Understanding the Basics of Automated MEP Clash Detection

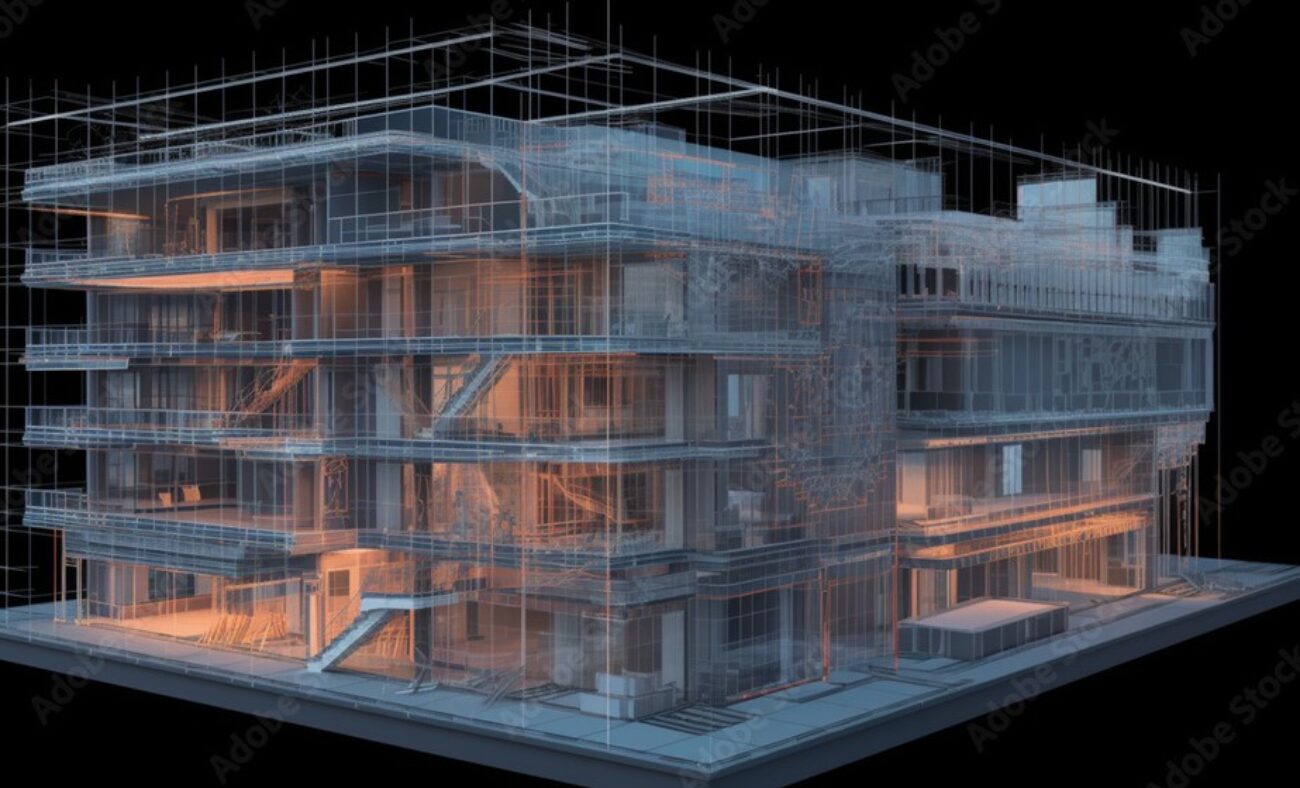

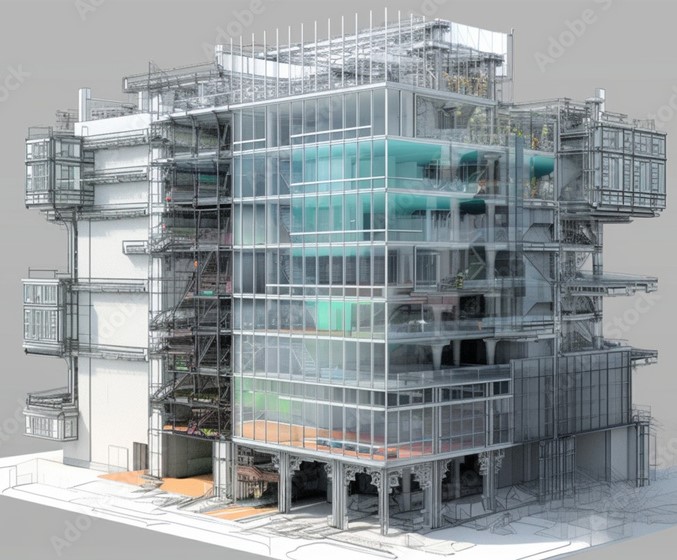

Automated MEP clash detection utilizes BIM software to create a virtual representation of a building project, encompassing all its systems and components. By analyzing the geometric and spatial relationships between these elements, the software can automatically pinpoint areas where clashes occur.

Visualization is a key aspect of this process. Most clash detection software provides 3D views and reports that highlight the clashing elements, making it easier for stakeholders to understand the nature and severity of the issue. This visual clarity facilitates quicker decision-making and more effective collaboration among team members. Moreover, automated clash detection fosters a collaborative environment where architects, engineers, and contractors can work together seamlessly to address potential conflicts before they escalate into costly on-site issues.

How Automation Enhances MEP Coordination and Design

By integrating automated clash detection into the design phase, project teams can proactively identify and address potential conflicts before they arise on site. This proactive approach streamlines coordination meetings, allowing stakeholders to focus on critical design decisions rather than spending time resolving avoidable clashes.

Incorporating automation early in the design phase empowers teams to make informed decisions. For instance, if a clash is detected between a ductwork run and a structural beam, the team can explore alternative routing options or make necessary adjustments to the structural design before it impacts the construction schedule. This iterative process optimizes both the MEP systems and the overall building design, creating a more efficient and cost-effective solution.

How is BAMROC Going to revolutionize MEP Clash resolution?

BAMROC stands as a testament to the continuous advancement of technology in the construction industry. This sophisticated software is designed to not only detect but also resolve clashes automatically, minimizing the need for manual intervention and significantly accelerating the coordination process.

Unlike traditional clash detection tools that merely highlight conflicts, BAMROC in the Middle East goes a step further by leveraging intelligent algorithms and machine learning to propose and implement feasible solutions. This includes suggesting alternative routings for ductwork or piping, adjusting the placement of electrical fixtures, or even modifying structural elements to accommodate MEP systems. This automated clash resolution capability empowers project teams, including structural engineers, to streamline their workflows and expedite decision-making, ensuring smoother project delivery with MEP clash detection services.

The Impact of Automated Clash Detection on Project Timelines

The integration of automated clash detection brings about a paradigm shift towards project efficiency. Contractors can avoid costly and time-consuming on-site rework by identifying and resolving clashes in the virtual environment during the design stage. This minimizes delays and keeps the project on schedule.

Early detection of clashes empowers project teams to address potential issues upfront, facilitating a more efficient design review and approval process. With fewer rounds of revisions and reduced back-and-forth communication, projects can move forward at an accelerated pace. Furthermore, this translates to faster project completion times, allowing developers to hand over projects to clients sooner and realize revenue streams quicker.

Case Studies: Time Saved on Real Projects with Revit

Real-world case studies provide compelling evidence of the time-saving benefits of automated clash detection in construction projects.

|

Project Type |

Time Savings |

Key Takeaway |

|

High-Rise Residential Building |

20% reduction in design coordination time |

Early detection and resolution of clashes minimized design revisions and rework. |

|

Hospital Expansion |

15% faster MEP installation time |

Accurate clash-free models ensured smoother on-site coordination and installation. |

|

Airport Terminal |

10% reduction in overall project schedule |

Proactive clash management prevented costly delays and expedited project delivery. |

Quantifying Time and Cost Savings in Indian Construction Projects: Reducing Rework

The adoption of automated MEP clash resolution solutions has witnessed significant growth in Indian construction projects. As the industry seeks to enhance productivity and deliver projects within budget and on time, the ROI of MEP solutions has become increasingly apparent. By minimizing on-site rework, reducing material waste, and optimizing labor allocation, automated clash resolution contributes to substantial cost savings.

Advantages of Integrating Automated MEP Clash Resolver in BIM

Automated MEP clash resolvers offer significant advantages when seamlessly integrated into a BIM workflow. This integration goes beyond simply identifying clashes; it empowers project teams to resolve them efficiently within their existing BIM environment. Improved communication and collaboration among stakeholders are also key benefits, as real-time clash detection and resolution information can be shared seamlessly between different teams.

Reducing Labor Costs Through Efficient Workflows: Construction cost saving by MEP Clash Removal

One of the most impactful advantages of integrating an automated MEP clash resolver is its ability to significantly reduce labor costs. By automating the clash detection and resolution process, these solutions free up skilled laborers from tedious and time-consuming manual tasks, allowing them to focus on more specialized aspects of the project.

Efficient workflows stemming from automated clash detection result in a streamlined approach to problem-solving. Instead of multiple iterations and revisions on site, conflicts are addressed virtually during the design stage, minimizing the need for rework and reducing the overall labor hours required for coordination. This translates into significant cost savings, as labor constitutes a considerable portion of construction project budgets.

"Building is not just about shelter. It's about realizing dreams, making statements, creating spaces where life happens"

Vavetek.ai Tweet

Avoiding Costly On-Site MEP Revisions: AI Visualizations

On-site revisions and rework rank among the major contributors to cost overruns in construction projects. These issues often arise when clashes between MEP systems and other building components remain undetected until the construction phase. Automated MEP clash detection, however, has the potential to eliminate these costly surprises.

By identifying clashes early in the design phase, these solutions drastically reduce the likelihood of on-site conflicts. This proactive approach not only minimizes the need for expensive and time-consuming rework but also prevents project delays and ensures a smoother construction process. Furthermore, avoiding on-site revisions allows contractors to adhere to project timelines more effectively.

Conclusion

In conclusion, automated MEP clash resolver tools are revolutionizing construction efficiency by streamlining MEP coordination and design processes. These tools not only detect clashes but also offer efficient resolution, saving valuable time and costs on projects. Integration of automated solutions like BAMROC can significantly reduce labor expenses and prevent costly on-site revisions, ultimately enhancing project timelines and overall productivity. Embracing automated MEP clash resolver in BIM workflows is a strategic investment that ensures smoother construction operations and higher project success rates.

Frequently Asked Questions

How does Automated MEP Clash Resolution Work?

Automated MEP clash resolution employs intelligent algorithms and AI to analyze BIM models. This analysis detects clashes between MEP systems, and the software often proposes solutions for resolving these workflow clashes, streamlining the coordination process.

What Are the Key Benefits of Automating MEP Clash Resolution for stakeholders?

Automating MEP clash resolution enhances project efficiency, reduces rework, and results in significant cost savings. Improved communication among stakeholders, fewer errors during construction, and adherence to project schedules are other notable benefits.

How Much Cost Savings Can Be Expected with Automated Solutions?

While the exact cost savings vary depending on project complexity, studies indicate that automated MEP clash resolution can lead to substantial reductions in overall project costs. BIM models facilitate this by providing a comprehensive view of the project.

Can Automated Clash Detection Integrate with Existing BIM Tools?

Yes, many automated clash detection software solutions are designed to integrate seamlessly with industry-standard BIM tools, including Revit, Navisworks, and ArchiCAD. This integration allows for a streamlined workflow and enhances the overall BIM coordination process.

Does BAMROC replace clash detection tools or it is only a resolver?

BAMROC goes beyond traditional clash detection tools by automatically running multiple iterations and generation complete resolution for all the design clashes. However, it leverages the capabilities of advanced clash detection tools rather than replacing them, creating a more comprehensive approach to MEP clash resolution.