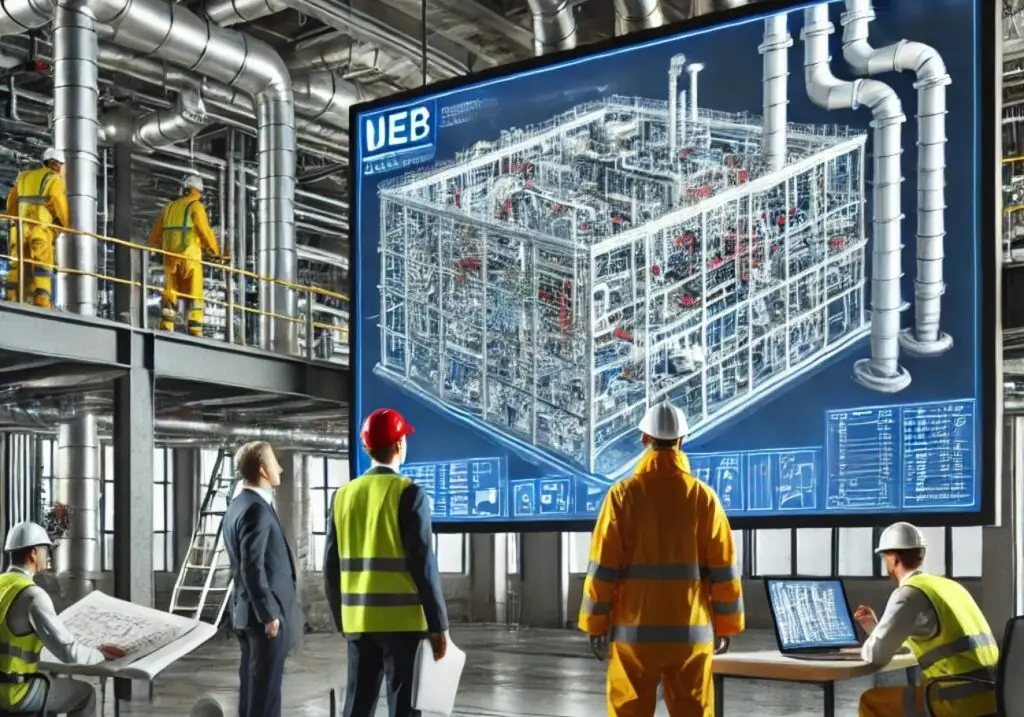

Imagine a world in which MEP engineers can foresee design conflicts before they occur, fine-tune energy efficiency at the touch of a button, and model real-world building performance months or even years ahead of construction. It’s not science fiction—it’s the reality of Building Information Modeling (BIM). By evolving outdated workflows into fluid, data-rich processes, BIM Benefit MEP engineers to overcome complex challenges with unmatched accuracy and ingenuity.

From streamlining plumbing layouts to optimizing electrical loads with AI-driven intelligence, BIM is more than a tool, it’s a revolution. But with great power comes great complexity. This blog takes a deep dive into the cutting-edge ways BIM is transforming MEP engineering, the challenges teams are facing in adoption, and the future trends that are breaking new ground in what’s possible in construction

What is BIM in MEP Engineering?

Imagine BIM as the holy grail of digital twins for buildings, a dynamic 3D representation that encases every bolt, nut, and pipe of a building’s physical and functional makeup. It’s not merely a pretty face, though; it’s an explosion of data and automation. For MEP engineers, BIM reimagines boring, time-consuming tasks as lean processes, massaging gigantic amounts of data to reveal secrets once hidden in blueprints or spreadsheets.

When used powerfully, BIM is an MEP professional’s precision instrument. It’s not about creating systems, it’s about perfecting them. From HVAC schematics that draw breaths of efficiency to electrical systems humming with dependability, BIM makes every part play nice with others. And the best thing? It spots mistakes before mistakes spot you, conserving time, money, and migraines.

Key Benefits of BIM for MEP Engineers

Adopting BIM in MEP engineering offers a range of benefits that go beyond simple visualization. It enables precision-driven decision-making, minimizes costly design errors, and enhances collaboration between different teams. Here’s how BIM is transforming the industry:

1. Enhanced Design Accuracy

With detailed modelling and data-driven insights, BIM helps identify design flaws before construction begins. This reduces errors, design clashes, and inconsistencies, ensuring high-quality MEP layouts. Engineers can fine-tune systems before installation, minimizing costly revisions.

2. Automated Clash Detection

BIM tools automatically identify and resolve conflicts between MEP components, structural elements, and architectural designs. This prevents costly rework and enhances project coordination. By detecting clashes early in the design phase, teams can avoid on-site issues, saving both time and money.

3. Improved Energy Efficiency

BIM enables MEP engineers to design energy-efficient HVAC, electrical, and plumbing systems by simulating various scenarios and optimizing resource utilization. This contributes to sustainable building practices by reducing energy consumption and improving system performance.

4. Faster Design Iterations

Traditionally, MEP engineers spend significant time manually refining designs. BIM accelerates this process by generating multiple design variations, allowing engineers to choose the best-performing option efficiently. This speeds up project timelines while ensuring optimal system functionality.

5. Predictive Maintenance and Smart Monitoring

BIM models can predict potential equipment failures in MEP systems using sensor data and historical trends. This helps in implementing proactive maintenance strategies, reducing downtime and repair costs. Facility managers can use BIM for ongoing monitoring, ensuring that systems remain in peak condition.

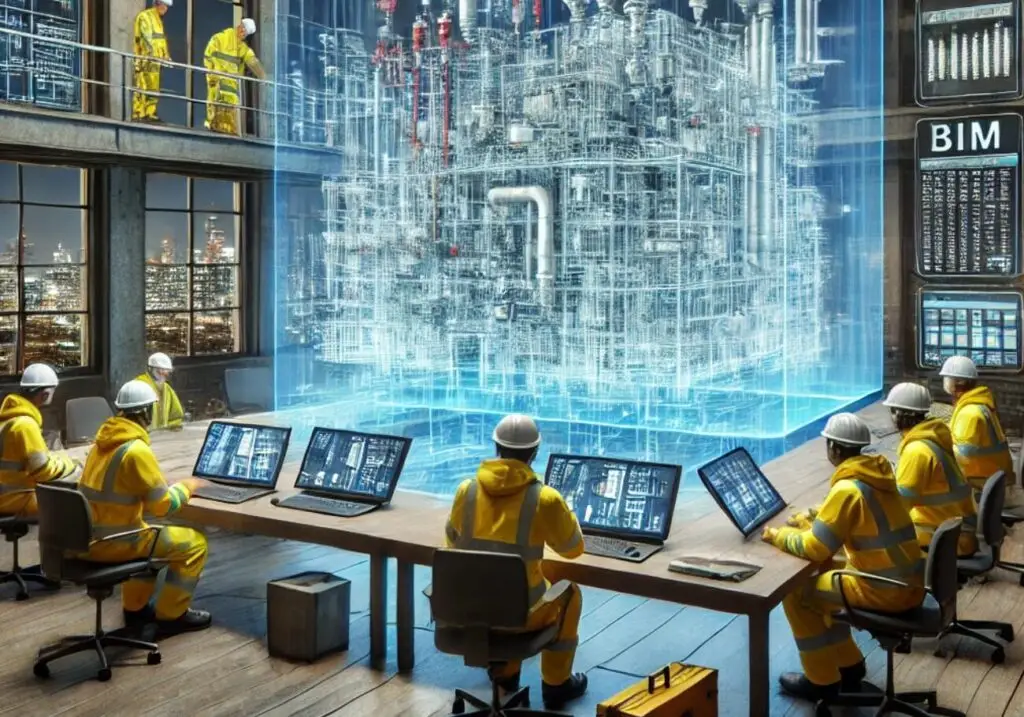

Applications in MEP Design and Coordination

BIM’s real impact lies in how it transforms MEP design and coordination, shifting from reactive problem-solving to proactive optimization. Engineers can simulate real-world conditions, ensuring every system is integrated efficiently before construction begins. Below are some of its key applications:

1. Optimized HVAC System Design

BIM enhances HVAC load calculations, airflow distribution, and thermal modelling, improving energy efficiency. Engineers can simulate different scenarios to ensure proper ventilation and temperature regulation and reduce energy waste.

2. Smart Electrical Load Balancing

BIM assists in balancing electrical loads, preventing power surges and improving system reliability. This ensures that electrical infrastructure supports the building’s needs while optimizing energy use.

3. Automated Plumbing System Optimization

BIM predicts water demand, pipe layouts, and drainage system efficiency, minimizing leaks and wastage. Engineers can simulate fluid dynamics, ensuring an efficient and reliable water supply system.

4. Digital Twin Integration

By integrating BIM with digital twins, MEP engineers can simulate real-world conditions and optimize building performance. This allows real-time monitoring, predictive analytics, and lifecycle management of MEP systems.

Step-by-Step Guide: Implementing BIM for MEP

Implementing BIM requires a structured approach to maximize its potential. From selecting the right tools to training engineers, each step plays a critical role in ensuring efficiency and success. Follow this structured guide for effective BIM adoption:

|

Step |

Action |

|

1 |

Choose a BIM software (e.g., Autodesk Revit, Navisworks) |

|

2 |

Integrate tools for clash detection, automation, and design optimization |

|

3 |

Use predictive analytics for energy efficiency and maintenance forecasting |

|

4 |

Train MEP engineers to leverage data-driven insights effectively |

|

5 |

Continuously refine models based on project data and feedback |

Challenges in Adopting BIM for MEP Engineering

Despite its advantages, BIM adoption comes with challenges that firms must address to ensure a smooth transition. Understanding these obstacles can help teams prepare and strategize accordingly.

1. High Initial Investment

BIM tools require significant software, hardware, and training costs, which may be a barrier for smaller firms. While the long-term benefits outweigh the costs, the initial investment can be challenging.

2. Data Management Complexity

BIM relies on large datasets, and organizing, processing, and interpreting this data can be challenging for teams unfamiliar with digital workflows. Proper training and data management strategies are essential.

3. Interoperability Issues

Ensuring seamless integration across different BIM tools and platforms remains a challenge, especially when collaborating across multiple disciplines. Standardization efforts are helping, but compatibility concerns still exist.

4. Compliance with Industry Standards

MEP engineers must align with regional and global BIM regulations, such as ISO 19650, NBIMS, and PAS 1192, which require expertise in data structuring and compliance.

Tools for MEP Engineers: Top Solutions

BIM tools empower MEP engineers to streamline workflows, detect clashes early, and optimize system efficiency. With continuous advancements in technology, selecting the right tool is crucial for maximizing productivity and ensuring seamless collaboration. Below are some of the most widely used tools in the industry:

- Autodesk Revit

Automates MEP system designs and clash detection, streamlining workflows while enabling seamless collaboration across disciplines.

- Navisworks Manage

Provides advanced model coordination and detects design inconsistencies, ensuring projects stay on track and clash-free.

- Solibri

Enhances model validation, code compliance, and quality assurance, making it a go-to for error-free, regulation-compliant designs.

- MagiCAD

Offers MEP-specific design solutions for HVAC, electrical, and plumbing systems, combining precision with user-friendly functionality.

- BAMROC

An AI-powered tool designed specifically for MEP coordinators, BAMROC automatically detects and resolves clashes at high speed. It analyzes conflicts, explores optimized solutions, and seamlessly adjusts MEP services, creating a clash-free environment for improved efficiency and accuracy.

- BAMDOC

A powerful solution for clash detection reporting and documentation, BAMDOC ensures structured issue tracking and clear documentation, helping MEP teams maintain compliance and coordination throughout the project lifecycle.

Adoption of BIM: Standards Across Different Regions

|

Region |

BIM Adoption Standards |

|

USA |

Follows National BIM Standard (NBIMS) integrating advanced analytics |

|

UK |

Complies with BS EN ISO 19650 for data management in BIM |

|

EU |

Focuses on sustainability and energy optimization |

|

ASIA |

Increasing adoption in smart city and infrastructure projects |

Future Trends: How BIM is Shaping MEP Engineering

1. Sustainability Initiatives

Future advancements will further reduce carbon footprints by optimizing energy and water usage in MEP systems. Engineers will have access to more sophisticated tools for tracking sustainability metrics.

2. Increased Use of Generative Design

BIM will autonomously generate and evaluate multiple design options for efficiency and sustainability, reducing manual workload for engineers.

3. Robotics in MEP Installation

Robotic automation, powered by BIM, will streamline MEP system installations, reducing labour costs and errors. Automated prefabrication is also gaining traction.

4. IoT Integration with BIM

Real-time data from IoT sensors will enhance predictive maintenance, system efficiency, and automated adjustments. Smart buildings will become more efficient and adaptive.

5. AR/VR in MEP Coordination

Augmented and virtual reality will enable real-time visualization and walkthroughs for MEP system validation before construction. Engineers will have better tools for error detection and client collaboration.

FAQs About BIM for MEP Engineers

What is BIM in MEP engineering?

BIM refers to the use of digital modelling, automation, and predictive analytics to enhance workflows.

How does BIM improve MEP design?

BIM improves MEP design by automating workflows, optimizing energy efficiency, detecting clashes, and enabling predictive maintenance.

What are the challenges of using BIM?

Challenges include high implementation costs, data complexity, and resistance to adopting digital solutions.

What BIM tools are available for MEP engineers?

Popular BIM tools include Autodesk Revit, Navisworks, Solibri, and MagiCAD.