Reducing Construction Project Delays with Automated MEP Clash Resolution Solutions

1. Introduction

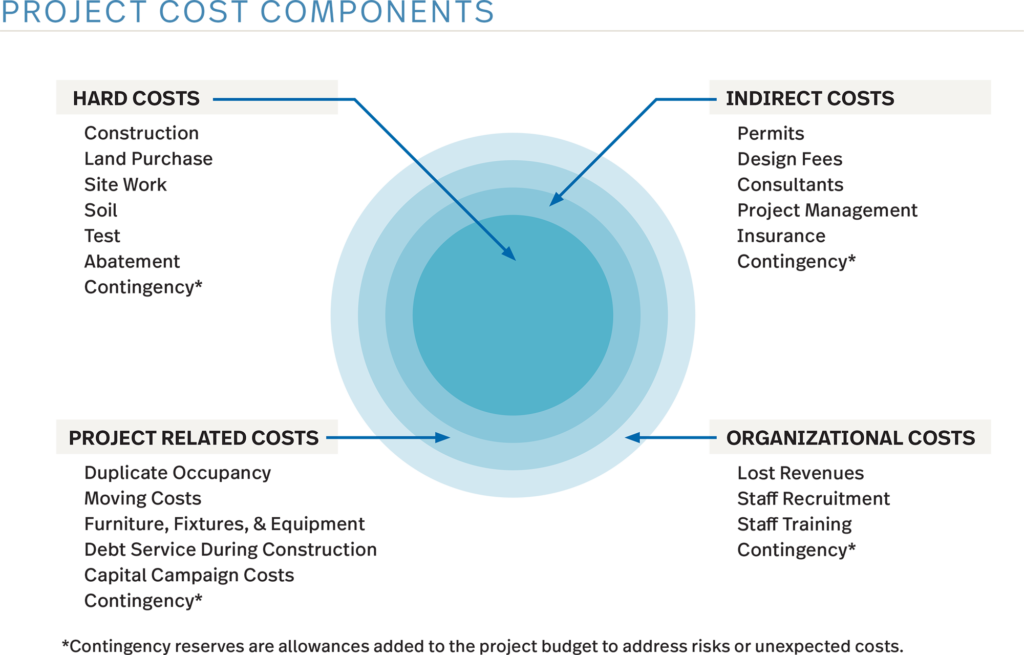

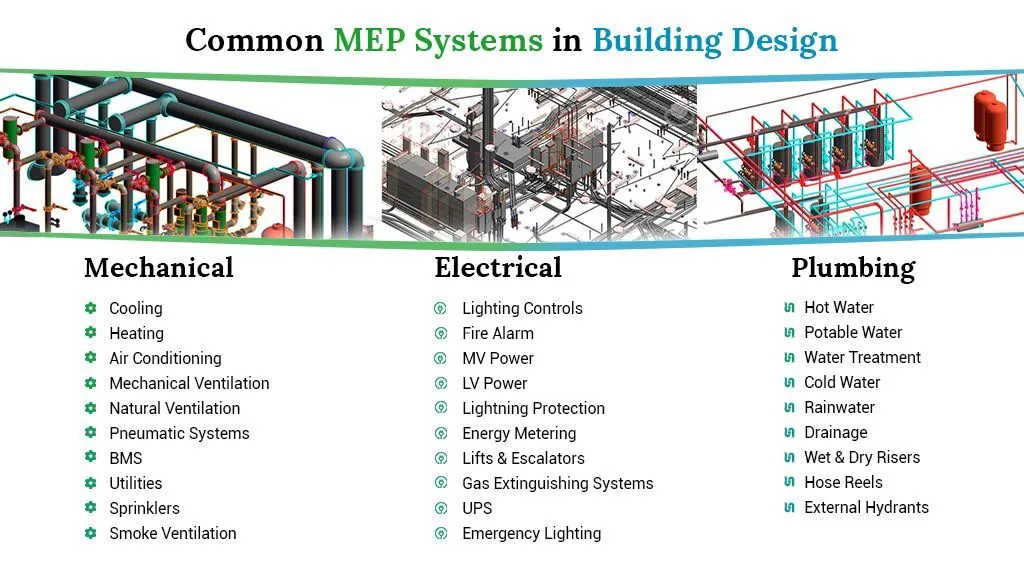

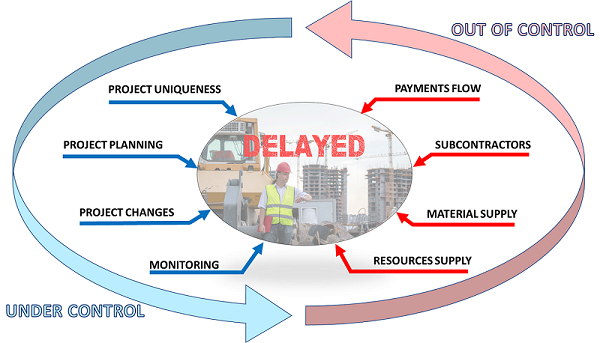

Delays in construction projects are a pervasive issue, affecting timelines, budgets, and stakeholder confidence. One of the most significant contributors to these delays is the presence of MEP (Mechanical, Electrical, and Plumbing) clashes in building designs. When systems like electrical wiring, HVAC ducts, and plumbing pipelines intersect improperly, they require costly on-site modifications that stall progress and increase costs. Traditional methods of identifying and resolving these clashes are often manual, slow, and prone to error.

At Vavetek.ai, we’ve developed BAMROC, an AI-powered software that revolutionizes MEP clash resolution. Unlike traditional tools that merely identify clashes, BAMROC goes further by automatically resolving them through millions of intelligent iterations to find the most efficient and viable solutions. This innovation ensures faster, more accurate resolutions, helping construction projects stay on track and within budget. In this blog, we explore how BAMROC and automated MEP clash resolution can significantly reduce delays in construction projects.

2. Understanding MEP Clashes and Their Impact

MEP (Mechanical, Electrical, and Plumbing) clashes occur when the paths of these systems intersect or interfere with each other in a building design. These conflicts can lead to significant challenges during construction, especially in large and complex projects. Resolving these issues early is critical to maintaining timelines and avoiding unnecessary costs.

Impact of MEP Clashes on Construction Projects

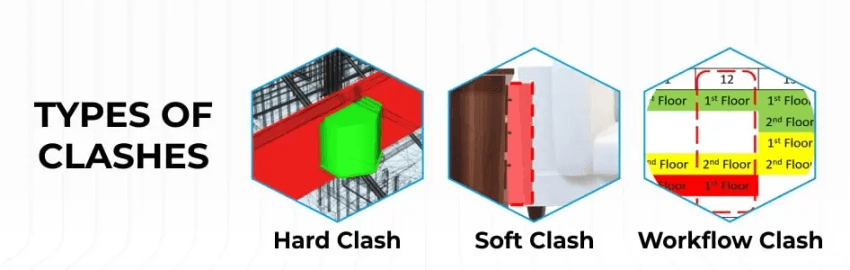

- Increased Costs:

Resolving clashes during construction leads to expensive on-site changes. Rework often accounts for 5-15% of total project costs, and MEP-related conflicts are among the leading causes.

- Delays in Timelines:

Unresolved clashes can result in days or even weeks of delays. For large-scale projects, each day of delay can cost between $20,000 and $100,000, depending on the project size and scope.

- Compromised Quality:

Last-minute adjustments can affect the overall quality and safety of the construction, as rushed fixes may not align with initial design intentions.

- Coordination Challenges:

Poorly managed MEP systems disrupt collaboration among design and construction teams, leading to confusion and inefficiencies.

Key Differences Between Manual and Automated Clash Resolution

Aspect | Manual Clash Resolution | Automated Clash Resolution (e.g., BAMROC) |

Accuracy | Relies on human inspection, prone to errors. | AI-powered algorithms ensure precise detection. |

Speed | Time-consuming, often delays the design process. | Resolves clashes in hours by running millions of iterations. |

Cost Implication | High due to extended timelines and rework costs. | Significant cost savings by reducing rework and delays. |

Scalability | Inefficient for large-scale or complex projects. | Handles complex designs seamlessly and efficiently. |

Outcome Quality | Varies based on human expertise and experience. | Optimized solutions with higher reliability and safety. |

How BAMROC Revolutionizes Clash Resolution

BAMROC, developed by Vavetek.ai, addresses MEP clashes through an automated, AI-driven approach. Unlike traditional tools that merely detect clashes, BAMROC resolves them by running millions of iterations to identify the most efficient, cost-effective solutions. Here’s how it works:

- Automated Resolution: Optimizes system layouts to eliminate clashes, saving both time and resources.

- Seamless BIM Integration: Works directly with Revit and other BIM platforms, ensuring real-time updates for all stakeholders.

- Accelerates Project Timelines: Reduces the clash resolution process from weeks to hours.

Estimated Cost and Time Savings with BAMROC

Project Size | Manual Resolution Cost (Approx.) | BAMROC Resolution Cost (Approx.) | Time Saved |

Small (< $5M) | $100,000 – $300,000 | $50,000 – $100,000 | 2-3 weeks |

Medium ($5M – $50M) | $500,000 – $1.5M | $200,000 – $400,000 | 4-6 weeks |

Large (> $50M) | $2M – $5M | $500,000 – $1M | 6-8 weeks |

By automating both detection and resolution, BAMROC reduces costs by up to 60% and saves weeks of valuable project time, making it a game-changer for construction projects of all scales.

With automated solutions like BAMROC, construction teams can prevent costly delays, streamline workflows, and ensure project success without sacrificing quality.

3. Manual vs. Automated MEP Clash Resolution

When addressing MEP clashes, project teams often choose between manual and automated resolution methods. Each approach has its strengths and limitations, but for large-scale or time-sensitive construction projects, automated solutions like BAMROC are rapidly becoming the preferred choice.

Manual Clash Resolution: Strengths and Challenges

Strengths:

- Flexibility for Small Projects: Manual resolution allows customization for simpler designs with fewer clashes.

- Human Expertise: Professionals can apply creative problem-solving based on their experience.

Challenges:

- Time-Consuming: Manually identifying and resolving clashes in complex designs can take weeks or months, delaying project schedules.

- Error-Prone: Human oversight increases the risk of missed clashes, leading to on-site rework.

- Costly: Extended timelines and additional labor for manual corrections often inflate budgets.

- Limited Scalability: For projects involving intricate systems or large teams, manual resolution becomes inefficient and unsustainable.

Automated MEP Clash Resolution with BAMROC

Key Advantages:

- Speed and Precision: BAMROC uses AI to automatically detect and resolve clashes, reducing the process from weeks to hours.

- Optimized Solutions: By running millions of iterations, BAMROC identifies the most efficient configuration for MEP systems.

- Cost Savings: Automated resolution minimizes expensive rework and prevents on-site delays.

- Scalability: Ideal for complex, large-scale projects with thousands of potential clash points.

- Integration with BIM: Works seamlessly with tools like Revit, enabling real-time updates and better collaboration.

How BAMROC Outperforms Manual Processes:

- Proactive Resolution: While manual methods react to identified clashes, BAMROC proactively prevents issues by optimizing layouts.

- Consistency and Reliability: AI eliminates variability in results, ensuring every clash is addressed with the same level of accuracy.

Why Automated Resolution is the Future of Construction

The construction industry is shifting towards automation to meet increasing demands for speed, accuracy, and cost-efficiency. BAMROC stands out as a game-changer by not only detecting clashes but also resolving them automatically—something traditional tools like Navisworks cannot achieve on their own. For construction teams looking to avoid delays and streamline operations, automated solutions like BAMROC offer unmatched advantages in quality, time, and cost control.

By adopting BAMROC, construction projects can move from reactive problem-solving to proactive, AI-powered design optimization. This transition ensures smoother workflows, better resource allocation, and timely project completion, setting a new benchmark in MEP clash resolution.

"Clash resolution isn't just a step in construction—it's the foundation for building the future. With AI-driven tools like BAMROC, we're not only solving problems but also redefining the way we design, collaborate, and construct."

Founder, Vavetek.ai

4. How BAMROC Helps Reduce Construction Delays

While traditional tools like Navisworks excel at identifying MEP clashes, resolving these clashes often requires significant manual effort. This manual process is time-consuming, prone to errors, and frequently results in delays. BAMROC, developed by Vavetek.ai, addresses this gap by focusing exclusively on automated MEP clash resolution, providing a seamless and efficient solution to a traditionally labour-intensive process.

How BAMROC Resolves Clashes Efficiently

- Optimized Resolution through AI:

BAMROC uses advanced AI algorithms to process millions of design iterations, identifying the most efficient and viable configurations for resolving clashes. This eliminates the need for human intervention and significantly speeds up the resolution process.

- Integration with Detection Tools:

BAMROC complements clash detection tools like Navisworks by seamlessly integrating with them. After Navisworks identifies the clash points, BAMROC takes over to automatically generate resolution strategies, saving project teams from laborious manual adjustments.

- Faster Resolution, Minimal Downtime:

Traditional manual resolution can take weeks or months, depending on the complexity of the design. BAMROC reduces this time to mere hours by automating the iterative process, ensuring construction projects stay on schedule.

- Scalability for Complex Projects:

Whether the project involves hundreds or thousands of clash points, BAMROC can handle the complexity with ease, making it ideal for large-scale or high-stakes construction projects.

Real-World Example: Reducing Delays with BAMROC

Consider a hospital construction project with over 2,000 identified MEP clashes. Using traditional methods, resolving these clashes would require weeks of coordination among engineers, resulting in potential construction delays. With BAMROC:

- The identified clash points from Navisworks are inputted into BAMROC.

- Within hours, BAMROC provides optimized solutions for each clash, factoring in system efficiency and compliance with design standards.

- Project teams implement the resolved layouts directly, avoiding weeks of manual work and ensuring construction progresses on schedule.

Key Benefits for Reducing Delays

Challenge | Manual Resolution | With BAMROC |

Time to Resolve Clashes | Weeks to months | Hours |

Risk of Delays | High | Minimal |

Resource Allocation | Requires large skilled teams | Minimal team input needed |

Scalability | Limited for complex projects | Handles thousands of clashes seamlessly |

By automating the resolution process, BAMROC minimizes the bottlenecks that traditionally delay construction workflows. It ensures faster resolutions, reduces dependency on manual labor, and provides project teams with the confidence to move forward without delays. This makes BAMROC an indispensable tool for modern construction projects aiming to stay on track and within budget.

Conclusion: Stay Tuned for Part 2

In this first part of our blog, we’ve explored the critical role of MEP clash resolution in reducing construction delays and how BAMROC, an AI-powered solution, revolutionizes the resolution process by offering optimized, scalable, and time-saving solutions. We’ve also highlighted the stark differences between manual and automated approaches, emphasizing BAMROC’s ability to streamline complex workflows.

In Part 2, we’ll dive deeper into the following aspects:

- 5. The Role of AI in Optimizing Construction Timelines.

- 6. Additional Benefits of Using BAMROC for MEP Clash Resolution.

- 7. Case Study: BAMROC in Action.

- 8. Why Choose BAMROC by Vavetek.ai?

Part 2 of this blog will provide detailed insights into BAMROC’s advanced capabilities, real-world applications, and how it sets a new standard for construction technology. Stay tuned to learn why BAMROC is the ultimate choice for overcoming MEP challenges in modern construction projects.